- Home

- Products

- Nondestructive Testing System (NDT)

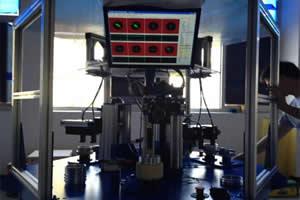

- Automatic Nondestructive Testing System (Testing Metal Aircraft Parts, Military Vehicle Parts, Heavy Equipment Parts)

Application:

The automatic nondestructive testing system (testing metal aircraft parts, military vehicle parts, heavy equipment parts) can be used in the following industries:

Military industry, space and aircraft industry, shipbuilding industry etc.;

Products of automobile industry and chemical industry such as bearing, cylinder liner etc.

Specification

1.Detection targets: parts;

2.Detection material: metallic material and some non-metallic material;

3.Detection mode: specially customized according to customer need;

4.Detection standard:

GB/T 7735-2004 Steel tubes--The inspection method on eddy current test.

YB/T 4083-2000 Measurement method of comprehensive properties for automatic eddy current flaw detection system for steel tubes.

GB/T 5777-2008 Seamless steel pipe and tubing methods for ultrasonic testing.

YBT4082-2000 Measurement method of comprehensive properties for automatic ultrasonic flaw detection system for steel tubes.

Detection method

The workpiece passes through feeding device to the detection area, then goes through machine control device specially designed for the workpiece, thus, realizing 100% coverage of the workpiece. After detection, the system will output automatic alarming, mark and sort signal, realizing full automatic flaw detection.

Features

The automatic nondestructive testing system (testing metal aircraft parts, military vehicle parts, heavy equipment parts) has the following features:

1.The automatic nondestructive testing system can be flexibly customized according to the workpiece features of our customers.

2.The automatic testing system can minimize the error caused by human operation.

3.The system can realize fast detection. It has higher precision and better stability at the same time.

COBE has the largest R&D center in China and an independent manufacturing center of NDT equipment. We can specially develop flaw detection equipment for various industrial parts such as bearing, cylinder liner, gun-barrel and other parts according to the product size, shape and testing requirements. The systems we developed has the following features: high detection speed, high precision and high reliability.