- Home

- Products

- Nondestructive Testing System (NDT)

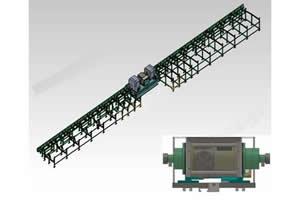

- Nondestructive Testing System (Rotary Ultrasonic Testing and Eddy Current Testing)

Application:

The nondestructive testing system (Rotary ultrasonic testing and eddy current testing) is designed for use on the following products:

Products of metallurgical plants and machinery plants such as steel pipes, titanium pipes, seamless steel pipes etc.

Finished and semi-finished bright bar, piston rod etc.

Specification

Detection targets: pipe, stick;

Detection material: carbon steel, stainless steel, copper, aluminum and other metallic material;

Detection speed: 0-8m/min;

Detection mode: eddy current ultrasonic offline testing.

Features

1.The combination of ultrasonic testing and eddy current detection can be flexibly adjusted according to practical requirements of our customer.

2. It can realize 100% precise inch by inch flaw detection of the surface and internal part of the workpiece.

3. It has great detection efficiency on cross and longitudinal defects of the internal of the workpiece.

More Info

This nondestructive testing system is a combination of rotary ultrasonic testing and eddy current testing. The eddy current testing is quite sensitive to surface and near-surface defects. Meanwhile, the ultrasonic testing can carry out precise flaw detection of the internal part of a workpiece. The combination of these two testing methods can realize 100% precise inch by inch flaw detection. The system is essentially foolproof.