- Home

- Products

- Nondestructive Testing System (NDT)

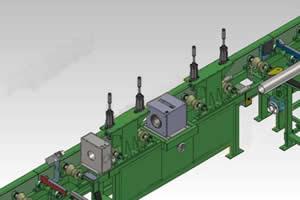

- Offline Nondestructive Testing System (Eddy Current Testing)

The offline nondestructive testing system (eddy current testing) can be used for unified flaw detection on finished workpieces. The workpieces loop through the automatic feeding device, roller bed, eddy current flaw detection area, magnetic saturator, probe, demagnetizer, and finally the unloading system. Then according to the detection results, the system will carry out automatic alarming, marking and sorting of workpieces according to those qualified and unqualified by the testing process.

Application:

The offline nondestructive testing system (eddy current testing) has the following applications:

Pipe material of middle and small diameter: seamless steel pipe, straight seam welded pipe, titanium tube etc.

Products of metallurgical plant and machinery factory such as steel bar, precision bright steel bar, high-speed tool steel bar etc.

Large diameter thin wall seamless pipe.

Specification

1.Detection targets: pipe, stick, profiled bar etc.

2. Detection material: carbon steel, stainless steel and copper, aluminum, titanium and other non-ferrous metals and ferrous metals

3. Detection speed: 0.1-100m/min

4. Detection mode: off-line flaw detection.

Features

1. High speed detection

2. All the equipment sets and mechanical systems are independently developed by COBE, thus, the running of testing equipment is highly stable and precise.