- Home

- Products

- Nondestructive Testing System (NDT)

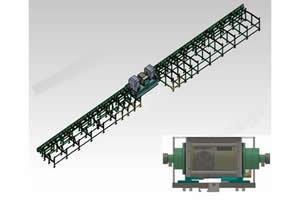

- Offline Rotary Ultrasonic Testing System

Application:

The offline rotary ultrasonic testing system can be used for flaw detection of pipes and rods with medium and small diameters. It can be used on components of metallurgical plants and machinery plants such as seamless steel pipes, titanium pipes, etc.

Specification

1. Detection targets: seamless pipe, stick etc.

2. Detection material: carbon steel, stainless steel, copper, aluminum and other metal materials and some non-metallic materials

3. Detection speed: 0-8m/min

4. Detection mode: offline rotary ultrasonic: the detection targets directly go through the ultrasonic rotating head.

Features

The target workpiece goes through feeding device, passing through the detection area straightly and the high speed rotary ultrasonic testing area, and then enters the automatic sorting and unloading device. This system is the best solution to realize high speed ultrasonic flaw detection with high precision and high stability.

Features

1. The offline rotary ultrasonic testing system has the fastest detection speed at present.

2. It has super high detection precision and stability.