- Home

- Products

- Nondestructive Testing System (NDT)

- Automatic Ultrasonic Nondestructive Testing System

Application:

In the aerospace industry, nuclear power industry, naval industry and some other fields, precision plate, pipes, rods, bearing are heavily utilized. These materials are used in harsh conditions with high temperatures, high pressures, complex loads, etc. Thus, disastrous consequences are realistic if these materials fail because of the existence of internal defects and defect extension. For these reasons, the flaw detection of these precision materials need the help of special NDT technology with high sensitivity, high resolving power and high reliability. The COBE-C-SCAN automatic ultrasonic nondestructive testing system is highly reliable. It can generate visualized detection results of material defects such as internal circumferential delamination crack, penetrating crack, inclusion, blowhole and loss of material density. It can show the distribution and severity of the defects of plates, rods, and other components.

Specification

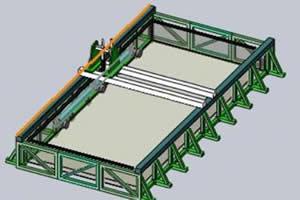

Water slot system: length ≤20m, width ≤8m, height ≤2m;

Digital ultrasonic equipment: 4~32 channels;

Reference standard:

GB/T 5777 Seamless steel pipe and tubing. --Methods for ultrasonic testing.

GB/T 2970-2004 Thicker steel plates --Method for ultrasonic inspection.

ASTM B594-06 Standard Practice for Ultrasonic Inspection of Aluminum-Alloy Wrought Products for Aerospace Applications.

BS EN 10160-1999 Ultrasonic testing of steel flat product of thickness equal or greater than 6 mm (reflection method).

ASTM E 2375-04 Standard Practice for Ultrasonic Examination of Wrought Products.

GJB 494A-2008 Specification for titanium alloy bars for aero-engine compressor blade.

SAE AMS STD 2154-2005 Inspection, Ultrasonic, Wrought Metals

Features

The COBE-C-SCAN automatic ultrasonic nondestructive testing system consists of the following 6 main parts: ultrasonic testing equipment, mechanical scanning device, electrical and automatic control system, flaw detection and automated assessment software, marking device, water treatment and a water circulation device.

More Info:

COBE has developed many COBE-C-SCAN automatic ultrasonic nondestructive testing systems of different scanning areas to solve the coupling stability effectively.

This automatic ultrasonic nondestructive testing system adopts precise multi-axis positioning technology to keep the position of detection target and the probe determined. This is an important way to ensure precise and reliable testing.

The system adopts supplementary digital flaw detector to show details of defect signals.

It uses flaw detection signal processing software to show distribution and severity of the defects of plate, stick and some other materials.

It has anti-interference design to reduce the effect of water interference, so that it can avoid error alarms effectively.