- Home

- Products

- Nondestructive Testing System (NDT)

- Online Steel Plate Testing System (Ultrasonic and Electromagnetic Ultrasonic Testing)

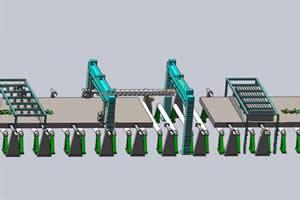

Online Steel Plate Testing System (Ultrasonic and Electromagnetic Ultrasonic Testing)

Application:

The online steel plate testing system (ultrasonic and electromagnetic ultrasonic testing) is designed for use on the following products: aluminum plate, titanium plate, copper plate, stainless steel plate, rare metal plate etc.

Specification

1. Detection targets: seamless pipe, stick

2. Detection material: carbon steel, stainless steel and copper, aluminum and other metallic materials and non-metallic materials

3. Detection speed: 0-8m/min

4. Detection mode: gantry: the steel pipe spinning on the spot while the probe moving left and right to scan it.

Detection standard

GB/T 2970-2004 Thicker steel plates -Method for ultrasonic inspection.

BS EN 10160-1999 Ultrasonic testing of steel flat product of thickness equal or greater than 6 mm (reflection method).

GB/T 8651-2002 Metal plates--Flaw detection method by the ultrasonic plate wave.

Features

The online steel plate testing system (ultrasonic and electromagnetic ultrasonic testing) developed by COBE can be customized according to the detection precision and efficiency of our customers. The system is an important way to ensure precision and reliability of detection.

The system is equipped with a digital flaw detector, so that it can show the details of defect signals.

It is equipped with a flaw detection specific signal processing software developed by COBE to show the distribution and severity of pipe defects.

The design of the pulse ultrasound and electromagnetic ultrasound has strong anti-interference ability, so that it can prevent false alarm effectively.

It adopts full automatic control and detection system to greatly improve the production efficiency and product quality.

More Info

The online steel plate testing system (ultrasonic and electromagnetic ultrasonic testing) has the following advantages:

1. Wide detection range: it can detect defects of aluminum plate, titanium plate, copper plate, steel plate, stainless steel plate, rare metal plate and some other kind of plate with different sizes it has strong adaptability because it is convenient to change detection targets of different material and specification.

2. Strong flaw detection capacity and high precision: the equipment can carry out 100% flaw detection without undetected targets.

3. Detection sensitivity is up to the precision standards of ASTM, ISO, EN, JIS and GB, so the detection results have good repeatability.

4. Fast and highly precise quality evaluation: it can carry out real-time precise localization of the internal defects of the material. And then mark the defects with the positioning error less than 20mm.

5. High level of automation and flaw detection efficiency: it has the following advantages: little manual intervention during flaw detection, easy maintenance without entering the equipment area, fast and convenient probe replacement and calibration while changing the target diameter.

6. The online steel plate testing greatly improves qualified rate of steel plate. It can cut the plate by avoiding the location of the defects so that it reduces reject rate of the cutting finished products.