- Home

- Products

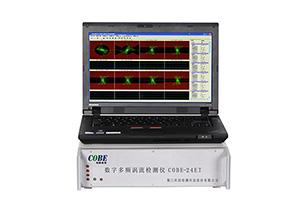

- Eddy Current Testing Equipment

- Portable Eddy Current Tester

- Portable Weld Seam Tester

Application:

The portable weld seam tester is designed for the detection of defects with high precision and speed. After detection, the unit evaluates the defects:

1. Testing aircraft components such as the alloy structure, framework, blades, wheel hub and undercarriage

2. Crack detection of the inner surfaces of aircraft rivets and screw bolt holes with or without fasteners

3. Testing metal components for a variety of industrial applications including nuclear power equipment, aerospace machinery, train engines, electric power equipment, petrochemical machines, and automobiles.

System parameters

CPU: ARM11 embedded 32-bit 500M processor

Operating system: Linux 2.6

Internal storage: 256M

External SD card: 8G

USB interface: full speed 12M/S USB-2.0 (Host/Slave)

Encoder: 1024 pulses/turn 0.1mm resolution

Operating language: Chinese, English

LCD luminance: 1-8 levels

Detecting parameters

Number of independent detection frequency: 2

Frequency range: 1KHz~1000KHz, stepping: 0.1dB

Gain: 0dB~99dB, stepping: 0.1dB

Phase: 0~359°, stepping: 1 Deg

Probe drive: Vpp=1~8V

Probe impedance: 50Ω, 100Ω

Gain adjustment of X and Y: Y/X= 0.1-10

Calibration curve: amplitude, phase, equivalent

Display mode: impedance, time base, Cartesian coordinates, polar coordinates

Scanning speed: 1-100 level

Center coordinates: X, Y adjustable.

Digital signal

Digital filtering: high pass (0Hz~2000Hz), low-pass (0Hz~2000Hz)

Filter sampling points: 1-1024

Broadband: 100Hz~10MHz

A/D rate: 16bit 100M

Minimum sensitivity: 1mV

Real-time average: 2, 4, 8, 16, 32

Auto balance: digital electrical equilibrium.

Storage of parameters and data:

Storage, deletion, editing of detection parameters: more than 10,000 groups

Storage, playback, analysis, saving, printing of real-time signal: 8G/24Hour

Detection picture: more than 10,000 groups

Save as: USB memorizer

Print: on-line, wireless.

Auxiliary systems

The system displays the calendar, time and battery capacity on the unit screen.

The operation is simple and convenient with real-time prompts on the screen.

There will be online HOTKEY graphics and text to assist the user.

Appearance and size

Length X width X height: 210mm X 60mm X 130mm

Monitor: resolution 640 X 480 5.7 inches TFT color LCD

Weight: 2Kg(including the battery)

Interface: LEMO-6 LEMO-15 DB-25

Lithium battery: 12V 3000mAH

Working temperature: -20℃~50℃

Features:

The ETP0202 portable weld seam tester is a highly valuable testing unit that makes use of electromagnetism theory to detect defects in metal components. It was developed by COBE engineers to solve the problems of traditional ultrasonic testing units that were too complicated and unreliable. The new testing unit is suitable for rapid detection and does not require the test surface to be extensively cleaned to achieve accurate results. The high sensitivity and precision of the seam tester is unrivaled and it can be equipped with intelligent detector units to improve detection efficiency and speed.

The technological parameters of the portable weld seam tester such as the frequency, gain and phase position should be pre-determined by the operator according to the task at hand. During the test, you can carry out detection at any time by choosing the corresponding technological parameters.