- Home

- Products

- Eddy Current Testing Equipment

- Portable Eddy Current Tester

- Digital Eddy Current Tester

Application:

The digital eddy current tester is used for defect evaluation on metal products such as blades, wheel hubs, undercarriages, and other aircraft components.

It carries out crack detection on the inner surfaces of aircraft rivets and screw bolt holes with or without fasteners.

The tester detects multilayered structures, aluminum skin, and fuselage-wing joints along with other aircraft parts.

The digital eddy current tester has an extremely powerful early diagnostic function to identify the stress concentration on metal structures.

Parameters

Calibration curve: amplitude, phase, equivalent

Display mode: impedance, time base, Cartesian coordinates, polar coordinates

Scanning speed: 1-100grades

Center coordinates: X, Y adjustable

Digital filtering: high-pass frequency (0Hz ~ 2000Hz), low-pass frequency (0Hz ~ 2000Hz)

Filter points: 0-1024

Broadband: 100Hz ~ 10MHz

A/D rate: 16bit 100M

Minimum sensitivity: 1mV

Real time average: 2 4 8 16 32

Auto-balance: digital electrical equilibrium.

Technical parameters of conductivity measurement:

Measurement range of conductivity: 0.5%IACS--110.0%IACS (0.28-64.0Ms/m)

Unit displayed: %IACS or MS/M

Resolution: 0.1%IACS

Lift-off effect: probe compensation 0.02”(500um)

Precision: ±1%IACS

Temperature compensation: there is a probe built-in sensor with automatic compensation function.

Data memory: it can store more than 10,000 testing data.

The results of conductivity measurement will be automatically corrected to values of 20℃.

Technical parameters of coating thickness measurement:

Base material: iron, non-ferrous material

Measurement range of conductivity: 0--1500μm (0--59.04mil)

Unit displayed: um or mil

Resolution: 1um

Precision: ±1um+1%(<50um) ±1um+2%(<100um) ±1um+3%(<500um)

Data memory: it can store more than 1,000 testing data.

Features:

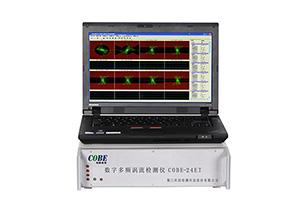

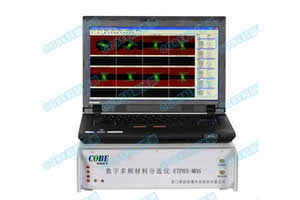

The COBE-ETP024D digital eddy current tester adopts advanced DSP and FPGA fusion technology, so that the signal processing speed, detection speed and precision are optimized.

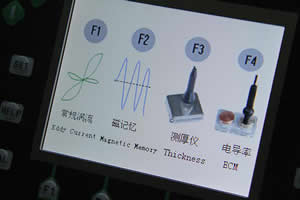

This digital eddy current tester is suitable for nearly all eddy current testing applications. It can effectively restrain any interfering signals. Besides the conventional digital dual frequency eddy current testing, it also has testing functions such as magnetic memory, conductivity and thickness measurement.

The operation of the digital eddy current tester quite automatic, thus, the operators can carry out the work immediately without long-term specialized training.